Facilities (UCLA)

Water Channel

A new 1.5m x 1.0m x 7m water channel tank with a 4-axis motion control system (pitch, plunge, translation, and rotation), transverse gust system, and active turbulence grid is currently being designed. Expected installation is summer 2026. Current development efforts include integration of a real-time control system with the existing model motion system.

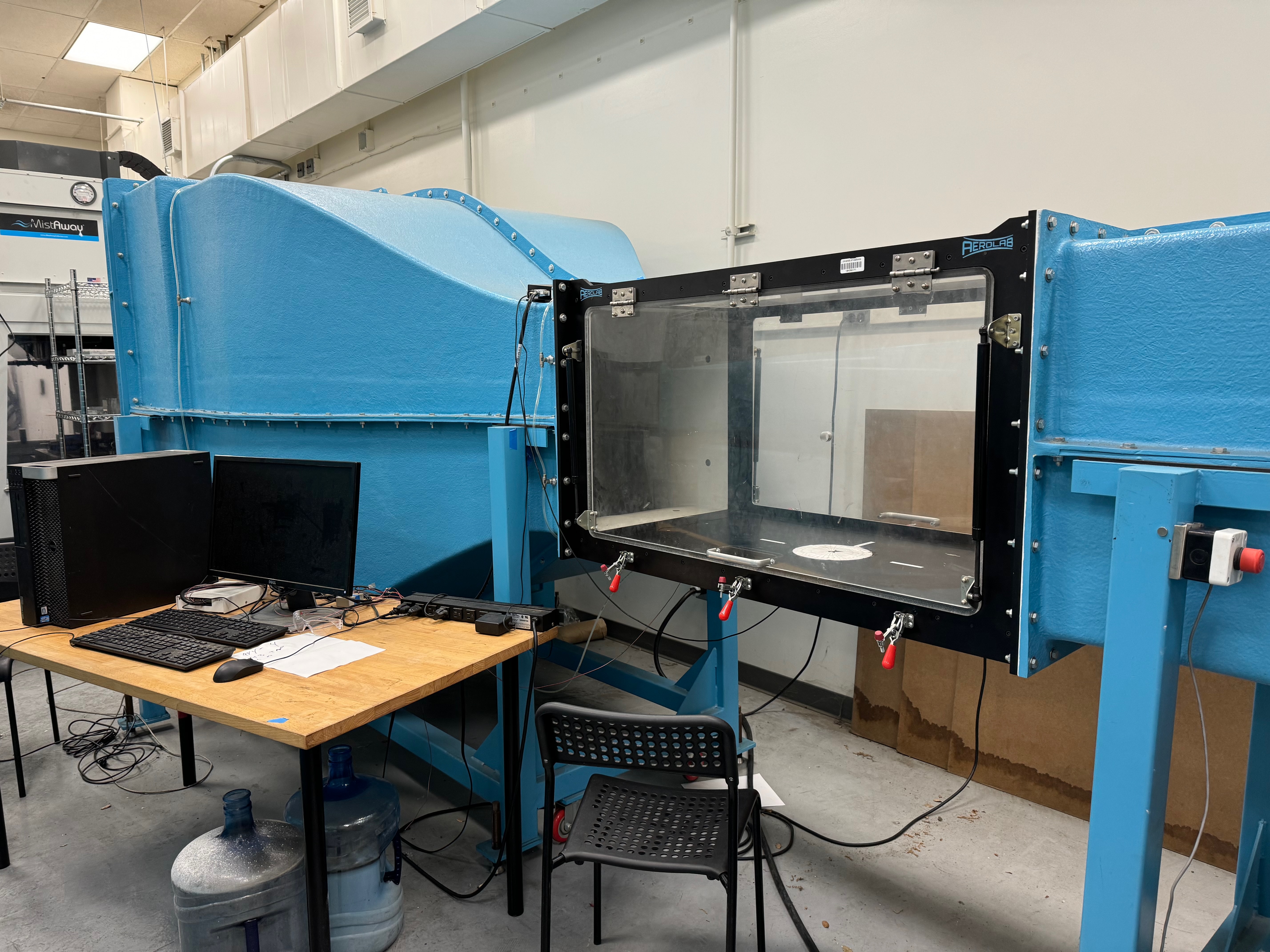

Wind Tunnel

The Department of Mechanical and Aerospace Engineering at UCLA has a 24in x 24in open-circuit wind tunnel with a maximum test section speed of approximately 67 m/s (150 mph). We are currently developing a lift-drag force balance and smoke flow visualization system for this facility.

Instrumentation

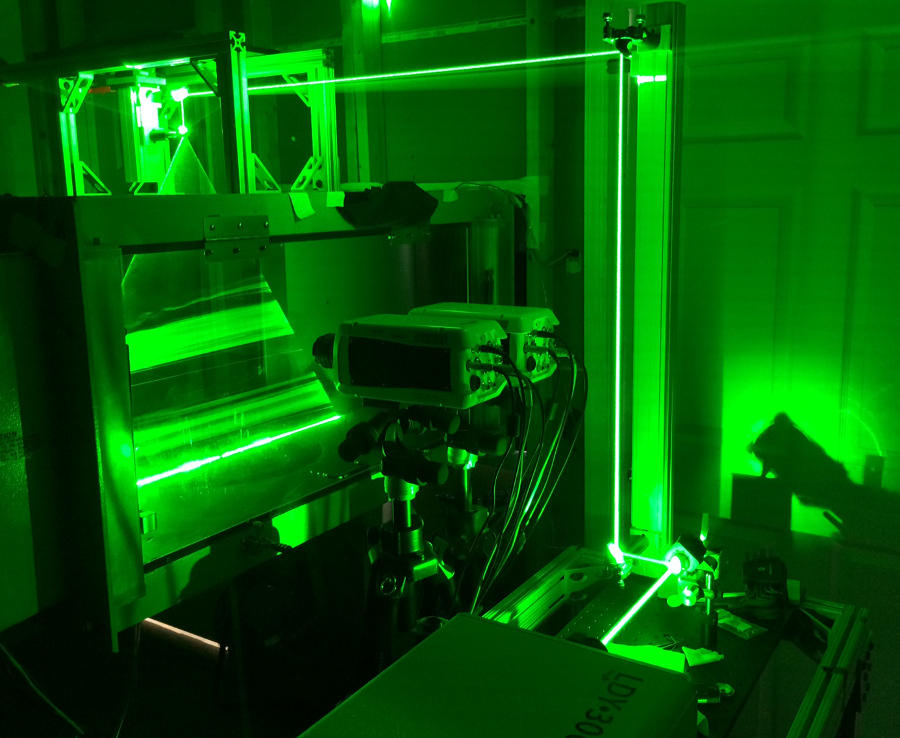

3D Particle Tracking Velocimetry (PTV)

The 4-camera 3D high-speed particle tracking velocimetry (PTV) system consists of four CMOS cameras capable of imaging at 1,400\,Hz with a resolution of 2650 x 1600 pixels, and a 30 mJ/pulse Nd:YLF laser.

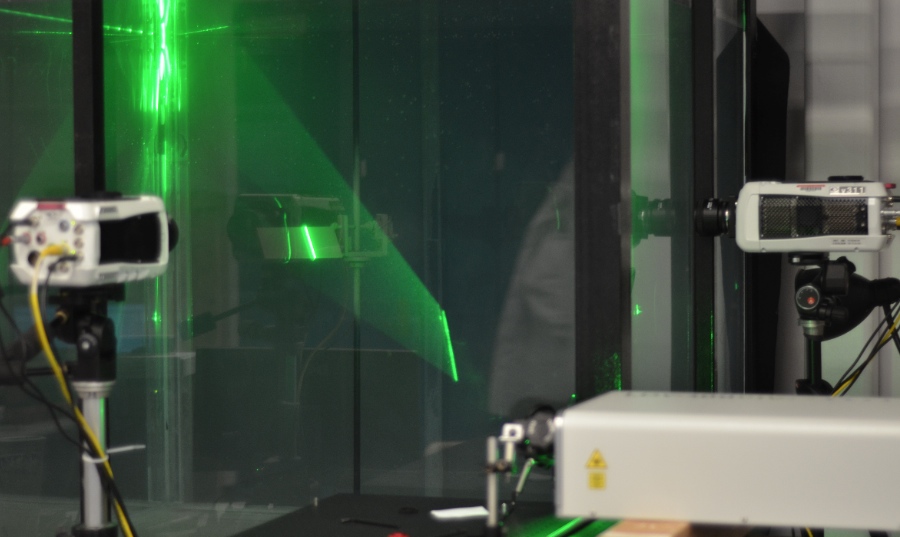

High-Speed Stereoscopic PIV

The high-speed stereoscopic particle image velocimetry (PIV) system consists of two CMOS cameras capable of imaging at 3,250 Hz with a resolution of 1280 x 800 pixels, and a 30 mJ/pulse Nd:YLF laser.

High-Resolution High-Speed PIV

The high-resolution high-speed particle image velocimetry (PIV) system consists of two CMOS cameras capable of imaging at 1,450 Hz with a resolution of 2,560 x 1,600 pixels, and a 20 mJ/pulse Nd:YLF laser.

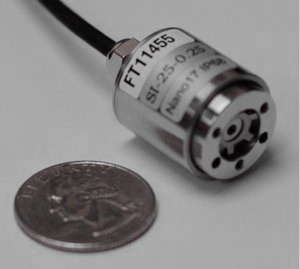

Submergible Force/Torque Sensors

Multiple ATI 6 degree-of-freedom submergible force/torque sensors (Nano25s and Mini40s), wireless capability, signal amplifiers, and data acquisition systems reside in the laboratory for use in the water tanks.

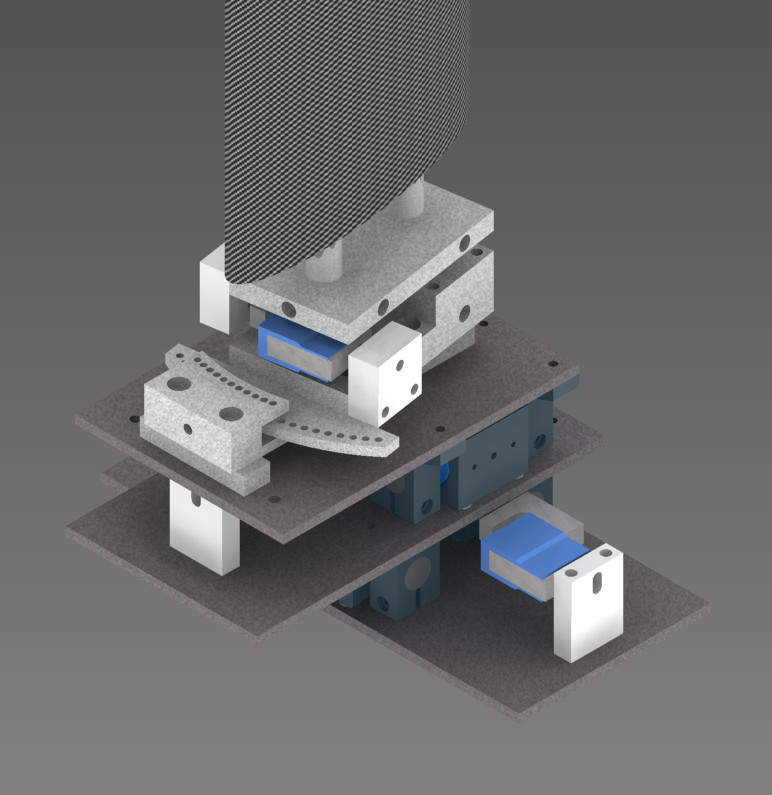

Unsteady Force Balance

This three-component force balance system was custom-built using high resolution load cells and linear air bearings to measure lift, drag, and pitching moment with nearly zero frictional loss. Model rotor blades are suspended between two force balances mounted above and below the test section of the 20 x 28 in open circuit wind tunnel. In addition to time-averaged measurements, this system is capable of sensing the frequency of unsteady aerodynamic forcing resulting from periodic vortex shedding.

Flow Visualization

The laboratory is equipped for both dye and laser flow visualization including a NE-300 infusion syringe pump, a 1 W continuous laser, and a Nikon d7000 camera (still images at 4928p × 3264p and HD video at 24 fps, 1920p × 1080p or 30 fps, 1280p × 720p) with tripods, lenses, and accessories.

Facilities (UMD)

Hover Tank

The hover tank is a 4ft × 4ft × 4ft (1.2m × 1.2m × 1.2m) water tank. The acrylic tank is housed in a steel structure that supports the bottom of the tank 3 ft above the ground to provide optical access on all six sides. An 80/20 aluminum frame is mounted around the top of the steel structure to provide support for experimental rigs. The laboratory also contains a 1.5ft × 1.5ft × 1.5 ft glass tank and accompanying 80/20 structure. This smaller facility is available for lower Reynolds number tests and/or experiments using other working fluids.

Wind Tunnels

The Department of Aerospace Engineering has several wind tunnels which we have access to, including the free-jet wind tunnel, the 20in x 28in open-circuit wind tunnel, and the Glenn L. Martin wind tunnel.

The 20in x 28in open circuit wind tunnel has a maximum test section speed of approximately 60 m/s (135 mph). This wind tunnel is currently being used to study the aerodynamics of a model rotor blade in reverse flow.

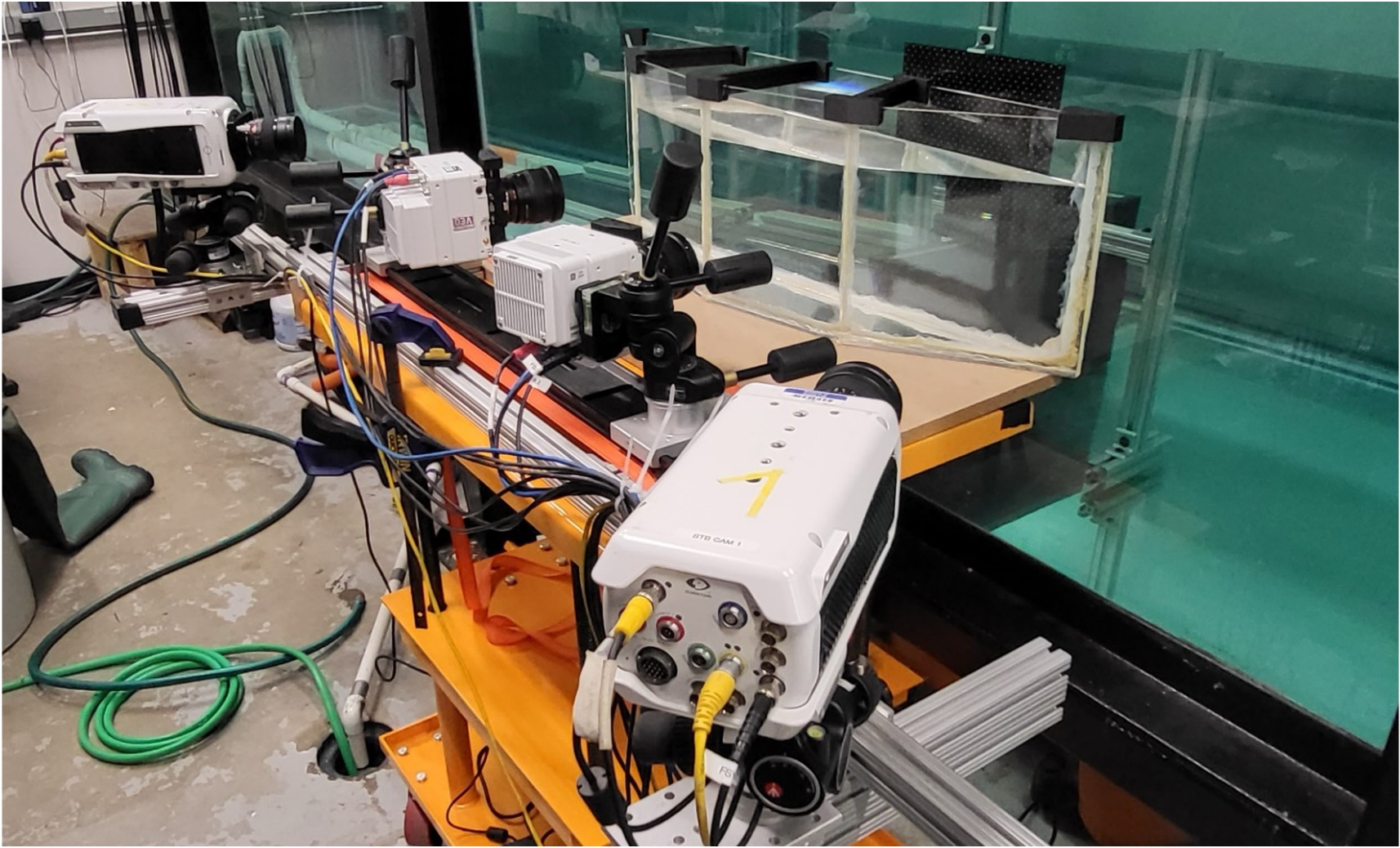

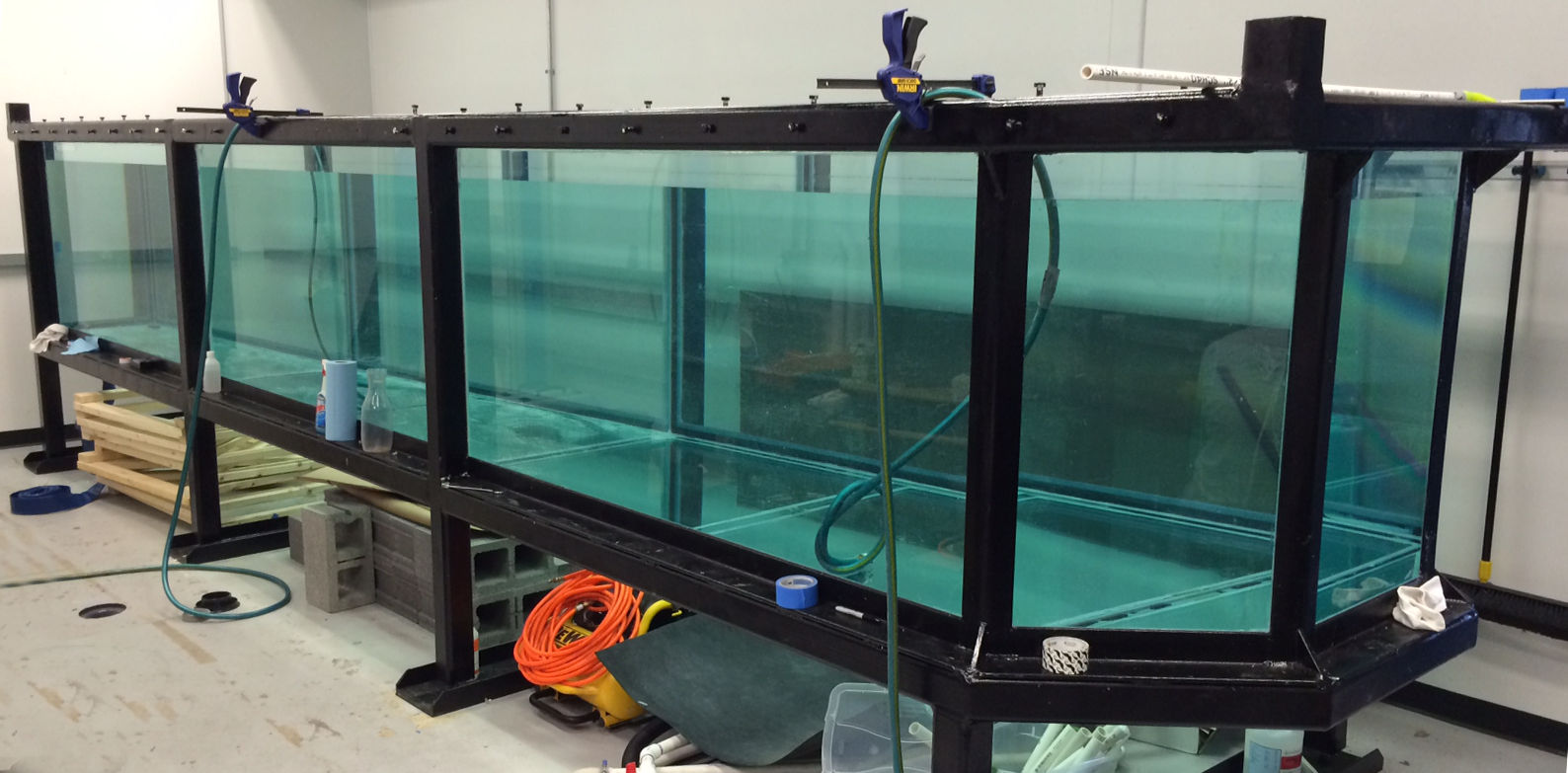

Towing Tank

A new 1.5m x 1.2m x 7m towing tank with a 4-axis motion control system (pitch, plunge, translation, and rotation) has been designed and constructed under a DURIP sponsored by AFOSR. The tank is also equipped with a set of 33 gust generators to produce an unsteady flow field for experiments on gust encounters.

ßDonec pulvinar ullamcorper metus

ßDonec pulvinar ullamcorper metus